Product

Catalogue Download / FCS_H300_V60.pdf

◇Application Examples of FCS System

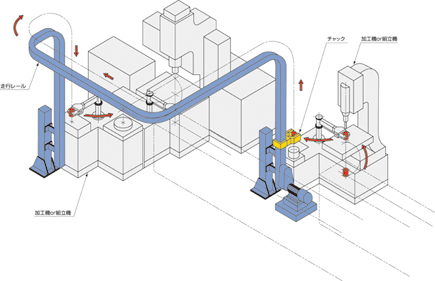

■Installing example for avoiding obstacle in process

work piece : geer/shaft roller/others small goods alignment conveyance

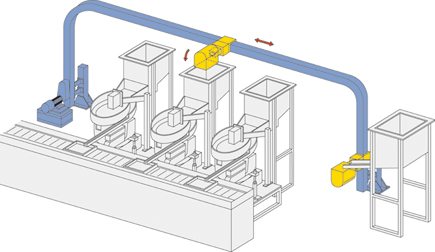

■Installing example for multi point stop conveyance

work piece : clincher / pin/ others batch conveyance

◇Advantage of FCS System

Trouble or pause in transportation occurs mostly at the time of mounting work pieces. While conventional system needs to tran-load work pieces many times in process, the FCS system does not trans-load work pieces till they are unloaded at the destination. Work pieces are kept in fixed position and conveyed without pausing unnecessarily.

①Forced conveyance

Prevents work pieces from getting hurt by collision, rubbing and so on. Production can proceed without any pauses of work flow caused by over tension or choke.

②Direct conveyance

As a single device drives three-dimensional conveyance, no error occurs in delivery of work pieces. Only a single chuck requires, because each work piece is carried direct to a designated place. It allows to be free from queue up.

③High speed conveyance

With a driving device placed separately, our unique system uses wire rope to perform both-way conveyance of work pieces. Each carrier is, therefore, compact and light in weight. Carrying speed is as high as 3m/sec.

④Space-saving

The system, designed compact, makes effective layout three-dimensionally. Our system doesn’t need conventional equipment for alignment, lifting up/down and reposition of work pieces, so that it saves great space.

⑤No step change

Using parallel chuck solves troubles of frequent steps change, happened on changing work pieces. Even when the shape of work pieces is very different, all it needs is to simply adjust or replace a chucking section.

⑥Multi-point stop

It is possible to make the carrier stop at many points where work pieces have to be collected or distributed.

⑦Many additional function

Besides the chuck function, the system can be equipped with many other functions, such as machinery of re-position, pickup, floating and so on.

⑧Easy Installation

Components are prepared by cutting to size, assembled provisionally and transported to the site, so that the system can be set up easily. Even upon a change of layout, the system is flexible enough to be readily adapted to the new layout.

⑨High quality, low price, and prompt delivery

All sorts of our products are manufactured by use of precision molds and special jigs and are, as standard products, kept in stock to be ready for prompt delivery.

FCS H-300 series

Conveyable weight 10kg, Conveyable moment 300kg・cm

Carrying speed 3m/sec

| H-300 specification | |||

| Carrying speed | 0~3m/sec | ||

| Carrying distance | Max.:40m/system | ||

| Conveyable weight | 10kg | ||

| Conveyable moment | 30N・m | ||

| mid-waystopping accurancy | ±1mm | ||

| Guide rail | Straight:Max3000mm Curve:400R90°or 45° | ||

| Carrier | Wheel×8+Guides×4 | ||

| Driving Device | Drive unit | ||

| Controller | FCS controller(TYPE 3) | ||

| Chuck | Chuck with air retention mechanism | ||

| Power source | 200/220V 50Hz/60Hz | ||

| Air source | Not less than 3.5kg・cm2 | ||

V60 series

Conveyable weight 3kg, Conveyable moment 60kg・cm

Carrying speed 3m/sec

| V-60 spesification | |||

| Carrying speed | 0~3m/sec | ||

| Carrying distance | Max.:20m/system | ||

| Conveyable weight | 3kg | ||

| Conveyable moment | 6N・m | ||

| mid-waystopping accurancy | ±1mm | ||

| Guide rail | Straight:Max3000mm Curve:400R90°or 45° | ||

| Carrier | Wheel×8 | ||

| Driving Device | Drive system | ||

| Controller | FCS controller(TYPE 3)※specification asbelow | ||

| Chuck | Chuck with air retention mechanism | ||

| Power source | 200/220V 50Hz/60Hz | ||

| Air source | Not less than 3.5kg・cm2 | ||

◇Comparison of each automatic handling system

| list of important item of handling automation | FCS | Gantry Loader | Handling Robot | Complex machine of conveyors and lifters |

| ●9 principles to prevent troubles of workpiece handlings | ||||

| Do not transport relying on gravity. | ◎ | ◎ | ◎ | ✕ |

| Do not release workpiece, once it has been caught. | ◎ | ◎ | ◎ | ✕ |

| Do not push workpiece by another one. | ◎ | ◎ | ◎ | ✕ |

| Do not leave workpiece without clamping. | ◎ | ◎ | ◎ | ✕ |

| Use guides?accurately in delivery and receipt | 〇 | 〇 | 〇 | △ |

| There is no perfect. Recovery from troubles has to be easy. | ◎ | 〇 | 〇 | 〇 |

| countermeasure for tramp material such as defective piece and foreign item. | 〇 | 〇 | 〇 | △ |

| Take attention to weld flash and lacking | 〇 | 〇 | 〇 | △ |

| Do not use same test piece many times. | ◎ | 〇 | 〇 | △ |

| ●17 principles for automation | ||||

| To adapt the speed of workflow. | ◎ | 〇 | 〇 | △ |

| To have enough conveyable weight. | 〇 | 〇 | 〇 | 〇 |

| Space Saving(Larger working place) | ◎ | △ | ✕ | ✕ |

| No trouble for handling. | ◎ | ◎ | ◎ | ✕ |

| Simple system and structure. | ◎ | × | 〇 | ✕ |

| Easy re-arrangement of layout. | ◎ | △ | 〇 | ✕ |

| Easy Changeover | ◎ | 〇 | ◎ | ✕ |

| No damage to workpiece(product). | ◎ | ◎ | ◎ | △ |

| Sefety | 〇 | △ | △ | 〇 |

| Not disturb its environment (eg noise) | ◎ | △ | 〇 | △ |

| Easy maintainance | 〇 | 〇 | 〇 | △ |

| Low price | ◎ | △ | △ | 〇 |

| Low running cost | ◎ | △ | △ | 〇 |

| quick delivery and installation | ◎ | △ | △ | △ |

| Not to make products in progress. | ◎ | ◎ | ◎ | ✕ |

| Countermeasures not to bring cutting chips and?oil?to next work. | 〇 | 〇 | 〇 | △ |

| No interfare with other machines and instructions. | ◎ | 〇 | ◎ | |

Technical Report 1 / Report-060831.pdf

Technical Report 2 / FCS_gantry_loader.pdf

Product Movie:JIMTOF (Japan International Machine Tool Fair)

Technical Report 3 / FCS_gantry_loader_参考図.pdf